The Ultimate Guide To Caster Manufacturer

Indicators on Caster Manufacturer You Need To Know

Table of ContentsCaster Manufacturer Can Be Fun For EveryoneThe Greatest Guide To Caster ManufacturerCaster Manufacturer - An OverviewFacts About Caster Manufacturer UncoveredAbout Caster Manufacturer

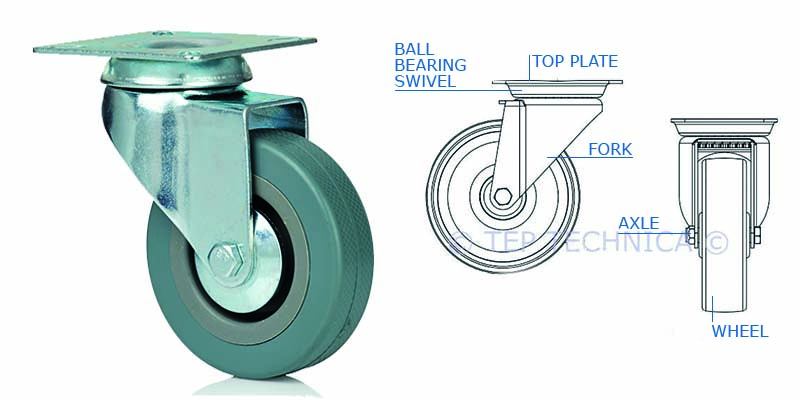

A basic, rigid wheel is composed of a wheel installed to a stationary fork.

An instance of this is the wheels found at the back of a buying cart in North America. Stiff casters often tend to restrict automobile motion so that the automobile travels along a straight line.

When the caster is moved as well as the wheel is not facing the correct instructions, the balanced out will trigger the wheel setting up to rotate around the axis of the upright shaft to follow behind the direction of motion. If there is no offset, the wheel will certainly not rotate otherwise facing the proper direction, either preventing activity or dragging across the ground.

A consequence of this is that the automobile naturally tends to travel in a straight instructions. Precise steering is not called for because the casters often tend to maintain straight motion.

The Facts About Caster Manufacturer Uncovered

The caster rotates perpendicular to the turning radius and also supplies a smooth turn. This can be seen on a purchasing cart as the front wheels turn at various speeds, with different turning span depending on how tight a turn is made. The angle of, and also range in between the wheel axles as well as swivel joint can be changed for various types of caster efficiency.

Industrial casters are strong casters that are designed to lug hefty lots, sometimes approximately thirty thousand extra pounds. An Industrial caster may have either a swivel or rigid wheel style. Industrial casters commonly have a level top plate that has four screw openings to make certain a tough link between the top plate and the lots.

An extra complicated sort of swivel wheel, often called a complete lock wheel, has an added rotational lock on the vertical shaft so that neither shaft pivoting nor wheel turning can happen, thus giving extremely rigid assistance. It is possible to use these 2 locks together or independently. If the vertical shaft is secured however the wheel can still turn, the wheel ends up being a directional caster, yet one which may be secured to roll in one direction along any kind of horizontal axis.

, hence the name kingpinless.

Getting The Caster Manufacturer To Work

An usual instance of wheel flutter is on a supermarket buying cart, when one caster swiftly turns side-to-side. This oscillation, which is additionally called shimmy, occurs naturally at certain speeds, as well as resembles speed wobble that happens in various other rolled automobiles. see page The speed at which wheel flutter takes place is based upon the weight borne by the caster as well as the range between the wheel axle and steering axis.

Flutter takes place when the caster is not in full call with the ground as well as therefore its alignment is uncontrollable. As the wheel regains complete call with the ground, it can be in any orientation.

At slower rates, the wheel's ability to swivel can correct the direction as well as can my site continue travel in the preferred direction. At high rates this can be dangerous as the wheel may not be able to pivot swiftly enough and the car might lurch in any direction. Electric and competing mobility device developers are extremely worried with flutter since the chair should be risk-free for cyclists.

The friction increases as the weight on the front of the chair boosts. Anytime the wheel begins to flutter, it reduces the chair and changes weight to the front wheels. There are numerous on the internet anti-flutter packages for retrofitting mobility device casters in this manner. Other techniques of reducing caster this content flutter include boosting swivel lead, using heavier grease, reducing the mass of the wheel, or enhancing rubbing with the ground by transforming products.

The Definitive Guide for Caster Manufacturer

Ergonomic wheels are developed with consideration for the operating setting as well as the task to be done to ensure that any adverse results on the driver are reduced. Long-term recurring actions involving standing up to wheels can add to stress injuries. Incorrect requirements can likewise contribute to minimized service life of wheels. Many criteria contribute in just how well the caster performs.

Large diameter wheel wheels have the ability to bridge voids like that between the floor as well as a lift auto. Nevertheless, the bigger the size of a caster wheel, the higher the caster support arm have to be. Either the base of a low-hanging item must be raised higher above the wheels, or the casters have to socialize sideways straddling the low-hanging sustained things.

Bigger wheels call for more of this room. Load ability might be raised by making use of bigger wheels with even more ground get in touch with area.

Each wheel has a fairly narrower ground get in touch with patch than a single vast wheel, so there is much less resistance to kipping down location on the swivel. There are 4 primary categories of wheels: A standard wheel has a facility revolving hub (or bearing) and a certified material on its outer side.

The 8-Minute Rule for Caster Manufacturer

An omnidirectional wheel (Mecanum wheel, Omni wheel, or Swedish wheel) is made from a large central center with numerous added smaller wheels installed along the perimeter such that their axes are vertical to the main wheel. The main wheel can rotate around its axis like traditional wheels, however the smaller wheels can likewise enable motion vertical to the central axis.

An instance is a ball transfer system (Caster Manufacturer).